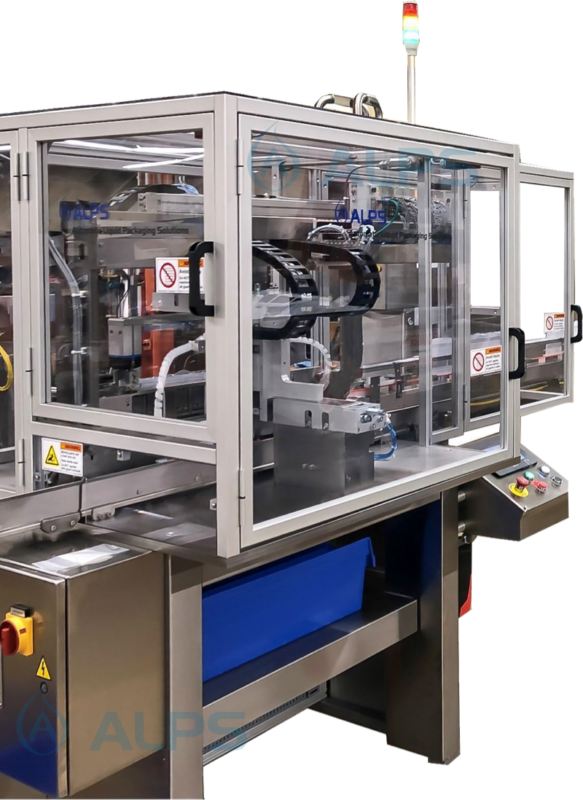

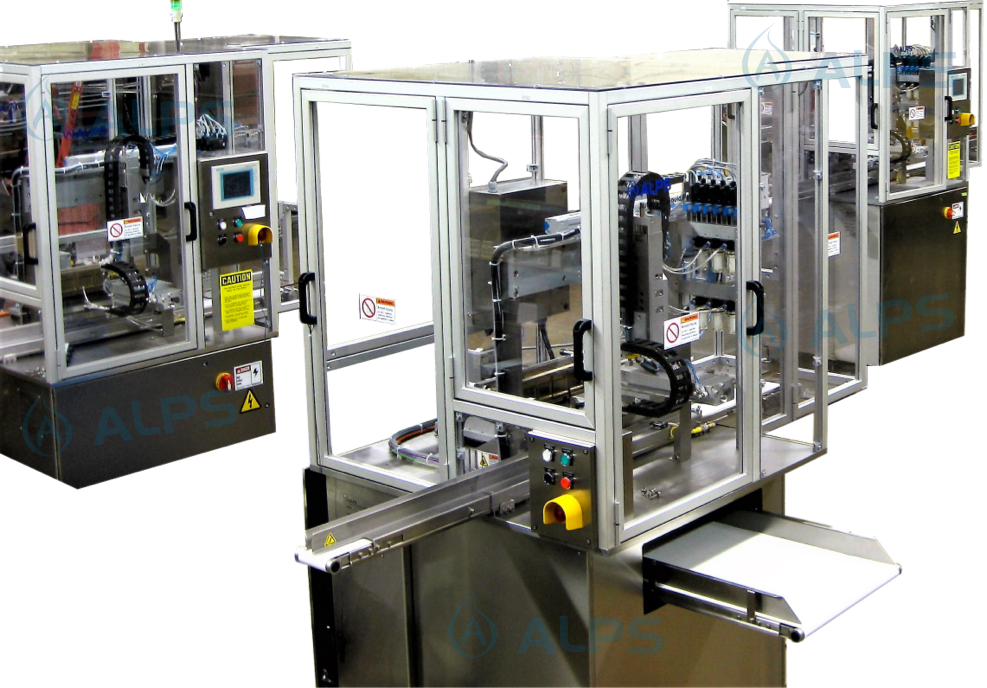

NEW! ALPS Hybrid 700 Series for BFS/FFS Technology

Designed and built with 43 years of experience & customer-focused approach.

ALPS 600 & 300 Series

.

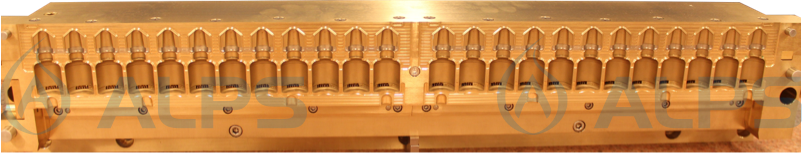

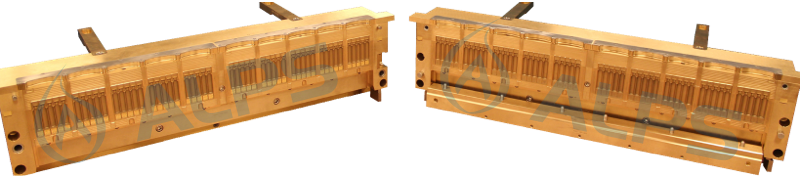

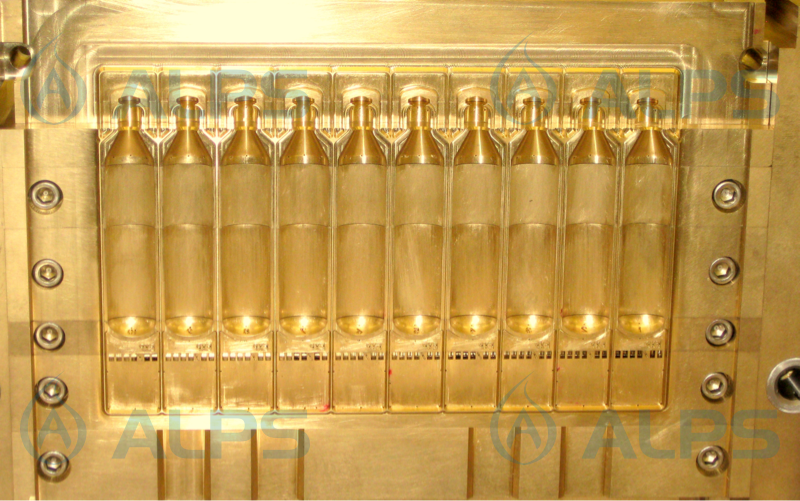

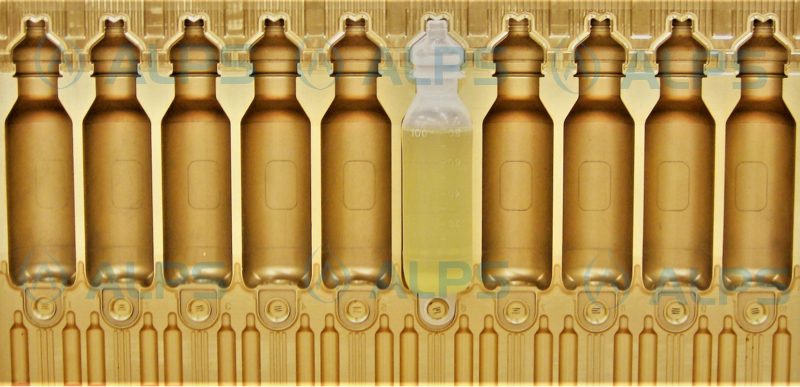

ALPS Molds

Examples of ALPS Molds For 700 Series Machines.

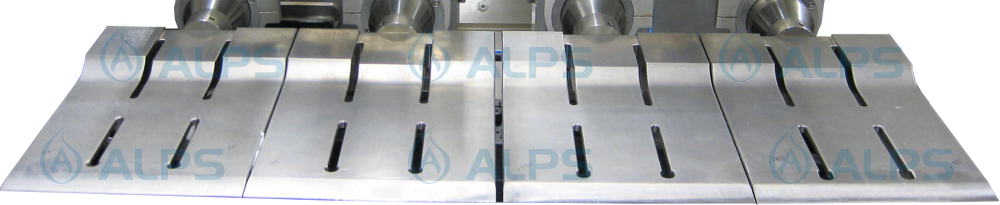

Isolation Insertion Technology (IIT)

ALPS Patented Deflasher

2mL - 5mL Vials

Up to 15,000/Hr

Respiratory/Inhalation

0.1mL - 1mL Vials

Up to 18,500/Hr

Eye Drops

50mL - 100mL Bottles

Up to 5,000/Hr IV Fluids

(Parenterals)

500mL Bottles

Up to 3,000/Hr IV Fluids

(Parenterals)

500mL Bottles

Up to 1,200/Hr

Humidifier

2000mL Bottles

Up to 800/Hr

Inhalation

2mL - 5mL Vials

Up to 15,000/Hr

Respiratory/Inhalation

0.1mL - 1mL Vials

Up to 18,500/Hr

Eye Drops

50mL - 100mL Bottles

Up to 5,000/Hr IV Fluids

(Parenterals)

500mL Bottles

Up to 3,000/Hr IV Fluids

(Parenterals)

500mL Bottles

Up to 1,200/Hr

Humidifier

2000mL Bottles

Up to 800/Hr

Inhalation

ALPS 600LN Series

ALPS 300LN Series